General Meeting

In the General Meeting, we discuss management of IDA, such as welcome events, reporting sessions, progress reports, safety management, and executives. Attendance of the General meeting is compulsory for all IDA members for safe and energetic activities. We have done the General Meeting via Zoom since 2020.

Lunch Meeting → ZOOM gathering

Lunch In the Lunch Meeting, we have lunch with IDA members to talk and interact with members from different projects. Since we are working on a project, opportunities to talk with members in other projects are limited. We sometimes discuss specific topics if necessary, but basically, we have lunch and a chat with IDA members. If you are interested in IDA, please feel free to join in this Lunch Meeting!

The ZOOM gathering is an activity that started in 2020 as a substitute for the Lunch Meeting. In addition to interacting with IDAcademy members, this is an opportunity to interact with IDA members before joining our club. The schedule is fixed at the beginning of each quarter. If you would like to interact with IDA members, we will inform you of the date and time and the ZOOM URL, so please add our official Line account.

Ongoing Project

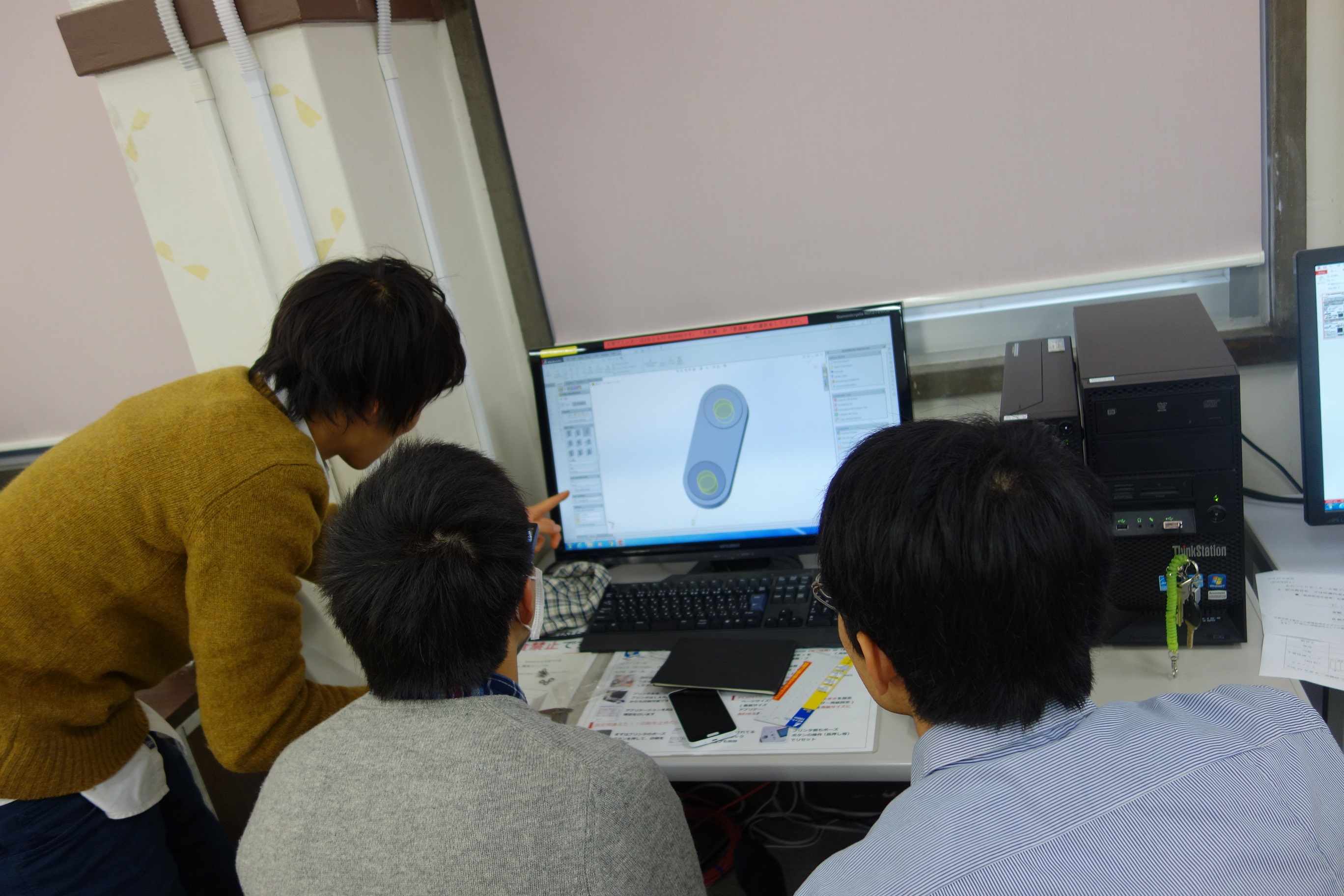

Cinnamon Project in Sri Lanka

In Sri Lanka, which accounts for 70% of the high-end cinnamon market, the cinnamon processing process relies on expert peelers. Currently, the experts get half of the production as a reward, so the farmer's income is less than half of the domestic average monthly income. To solve this problem, the Cinnamon Project is working to develop and disseminate low-cost and simple cinnamon processing equipment that anyone can use to process cinnamon trees. You can experience a series of steps starting from fundraising, establishing a business model, prototyping, and conducting a field survey. We got a grant of 700,000 yen from Tokyo Tech Startup Fund hosted by the Office of Research and Innovation in Tokyo Tech. If you want to start something from the beginning or try something without fear of failure, Why don't you join us?

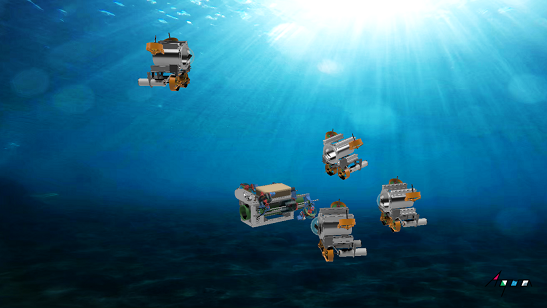

View Ocean Project

There are multiple social issues along coasts. In this project, we are going to tackle those issues by collecting visual data using swarm underwater robots. This project has lunched in 2022. We are planing to use ships to make it easy to use the robots. This project is co-project with Aqua in robotics clab in Tokyo Tech.

Past Project

Mondialogo Project

In 2009, we invented "a low-cost food storage system" and introduced it to a community in Nepal, and won a gold prize in the Mondialogo Engineering Award. This is our first activity as IDAcademy. Most of the members are international students majoring in International Development Engineering.

Prosthetic Leg Project in India

Prosthetic Leg Project is aiming at the development and dissemination of low-cost prosthetic legs in India. We collaborated with Dr. Ken Endo in Sony Computer Science Laboratories Inc. and Jaipurfoot, a clinic in India. The main activities in this project were to learn about human walking and structures of conventional prosthetic legs from research papers and the improvement of prosthetic legs.

Bio-Charcoal Project in Nepal

In Nepal, most of the fuel used at home is logging, and excessive logging of forests and health hazards to people due to indoor burning of firewood are severe problems. Therefore, we, Nepal Bio-Charcoal Project, aim to solve the problem by establishing the production technology of bio-charcoal made from agricultural waste and livestock excrement, and its sustainable dissemination system. In the summer of 2016, we stayed in Nepal for about two weeks and conducted biochar production experiments, interviews, and workshops for the local people.

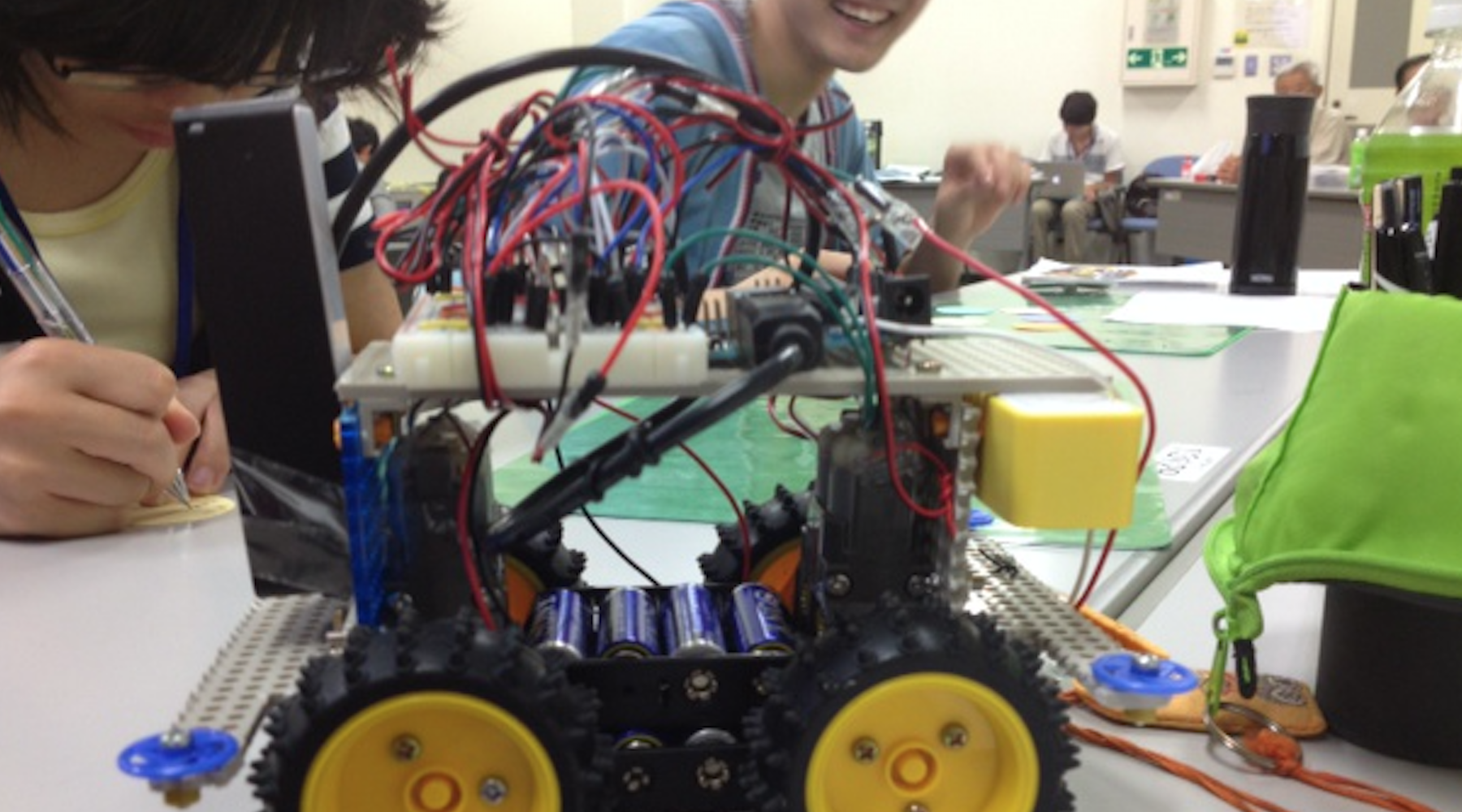

Shamo Robocon!

We provided science education for upper elementary school students at Kawamata Town in Fukushima. Since the Great earthquake disaster of East Japan, part of the budget for science education has been used for reconstruction support, so the science education that was conducted before the earthquake could not be implemented. Therefore, IDAcademy paid attention to "Kawamata Shamo" which plays a part in the local industry. However, Shamo is surprisingly unfamiliar to the local people. Therefore, for the deep understanding of science education and local industry, we planned to make Shamo robots, and let them fight like cockfighting. Elementary school students made robots and let them fight and experienced the essence of manufacturing and engineering. The first in March 2013, the second in August 2013, Shamo Robocon! has been held every year for four years until August 2016. The workshop is upgraded every time and is entertaining local elementary school students.

Compost project in Philippines

The compost project was started in the spring of 2014 to prevent water pollution caused by toilets, which is a problem in developing countries, and at the same time improving the income of the poor. Specifically, we are planning to establish a mechanism to use human waste, which is the cause of pollution, as a raw material for compost, liquid fertilizer, and biogas, and return a part of the sales of those products to the toilet users. Concurrently with the fieldwork needs survey in the Philippines, we conducted a biogas production experiment in Japan by fermentation using artificial feces charcoal.

Bio-Charcoal Project in Kenya

The Kenya charcoal project was started when one of our members realized the poverty and health problems in the rural area of Kenya during his stay for six months in 2010. In particular, the smoke generated by burning agricultural waste materials directly during cooking is harmful to the inhabitants. Therefore, we aimed to develop and disseminate the technology to make charcoal from agricultural waste materials which are available locally. Through the field research during summer and winter holidays and technological development in Japan, we have succeeded in improving each manufacturing process such as carbonization, crush, and pressing, and enhancing the quality and production efficiency of charcoal. We conducted a survey of residents and restaurants that use charcoal, and also worked on the development of a system to continuously disseminate the produced charcoal to the residents.

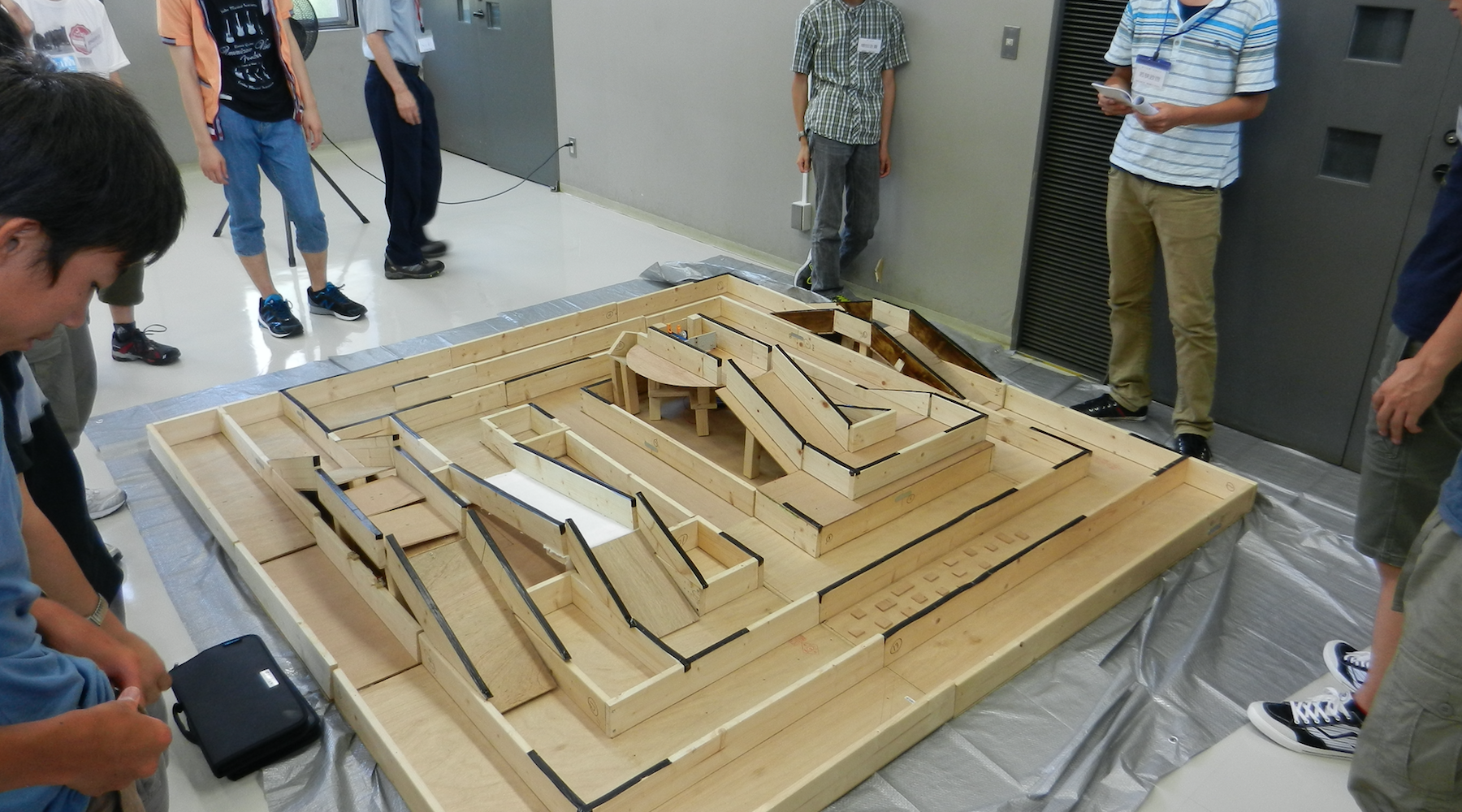

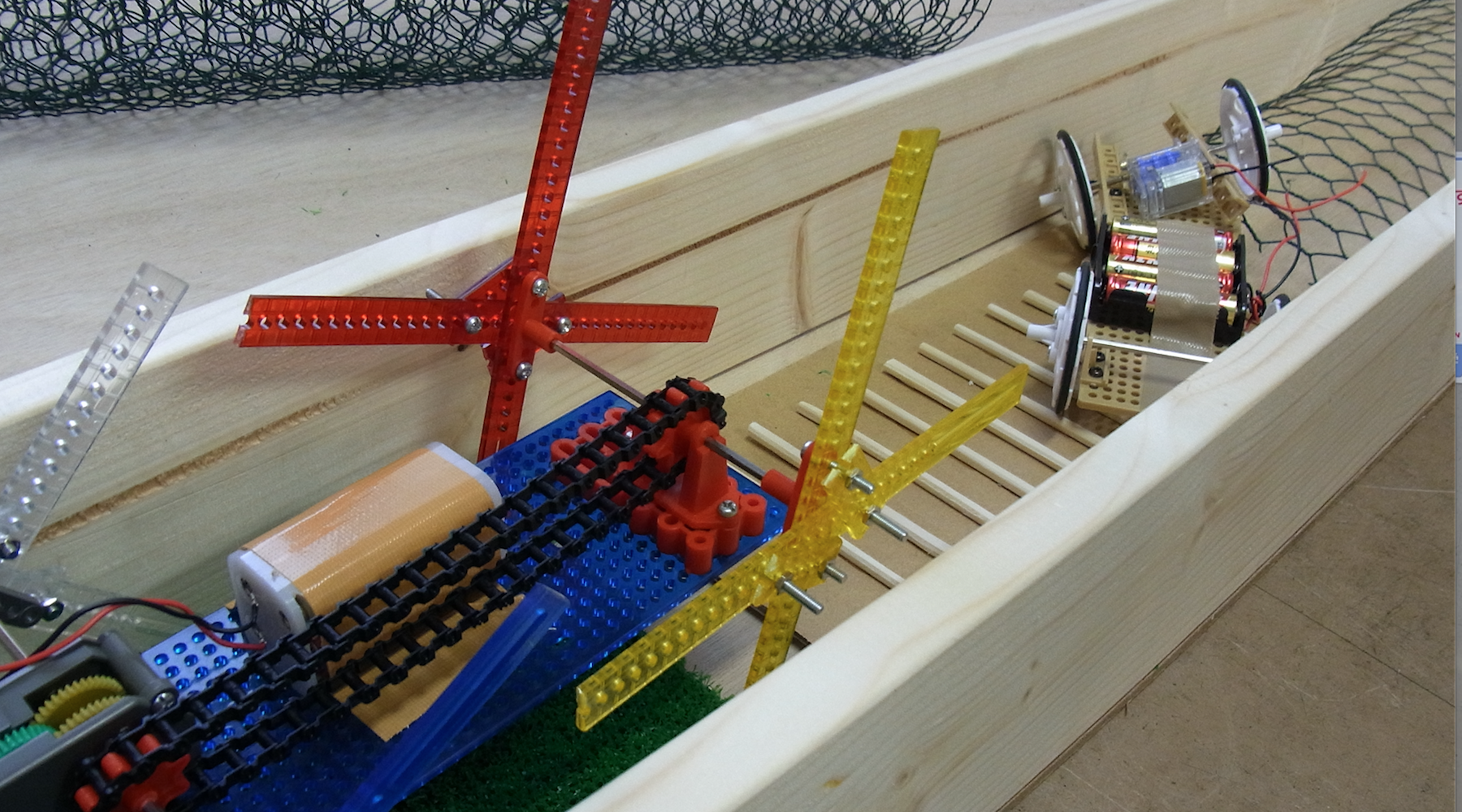

Monozukuri Workshop

The Monozukuri Workshop is a project that was carried out for elementary and high school students in Tokyo from 2011 to 2013 with the cooperation of the Kuramae Engineers Association. In the summer of 2011, students produced a non-electrified foot fan and a hand-cranked flashlight. In the summer of 2012 and the summer of 2013, students made cars with analog and digital controls, and let them travel through a course that IDA members made. This project was carried out so that students could experience the joy of manufacturing as a place for output, based on our experience like "When I was in high school, most of the school curriculum was classroom lectures, and I didn't have a place to make things and learn by using my hands.", "The purpose of study tends to be for passing the entrance exam.". As many as 70 elementary and high school students participated in the event, and each of them brought back their motivation for the current lecture and manufacturing.

Halal Project

Halal food, which Muslims can eat, is not well known in Japan now, and Muslims have less choice of food in Japan. To tackle this problem, we worked together with two Muslims at the University of Tokyo and the National Graduate Institute for Policy Studies to break through such a situation.

Non La Project in Vietnam

In September 2011, according to the request of a Vietnamese student, we launched a life improvement project in his home village (Dao Kate On Village, Nam Dinh Province). As a result of conducting needs surveys twice, we decided to focus on the shade (leaf hat) that farmers make as a side business during their farmworks. In 2012, we redesigned the leaf hat and held a workshop for a large number of farmers to make small souvenirs with the motif of the leaf hat, and at the same time supported the construction of its sales network.